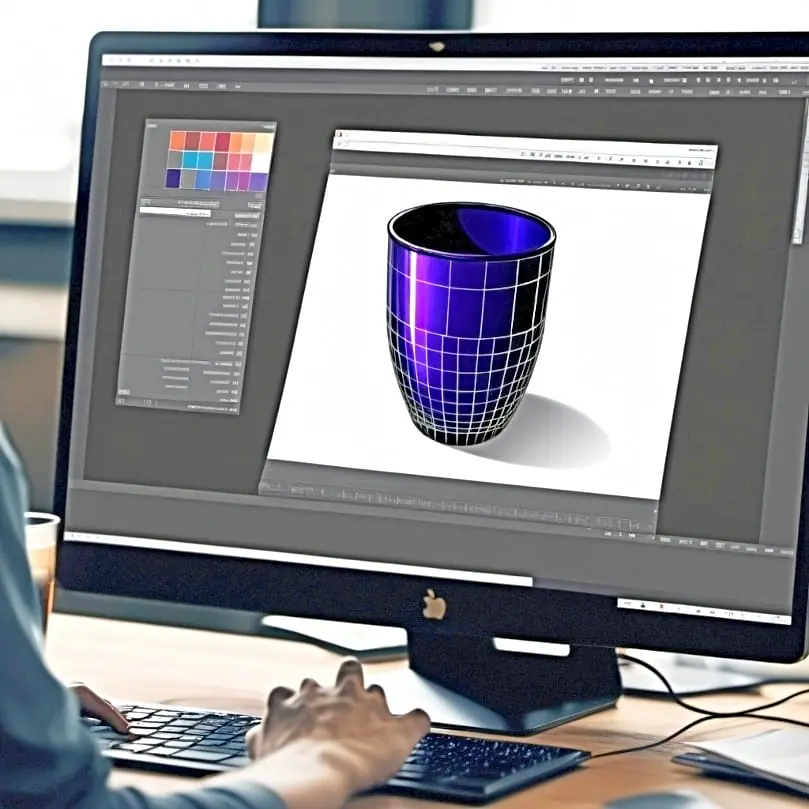

Sublimation is the primary method for personalizing products and also what we turn to for custom gifts. From birthday presents to wedding favors to corporate branding at event we see sublimated tumblers which are at the same time fashionable and functional. Also what makes them so attractive is that they present high quality full color designs which don’t come off after washing or fade over time.

That said, what you need to know is that professional results from sublimation aren’t by chance. In this process the key element is the right use of your sublimation heat press settings. If your press time, temperature or pressure is off you may get blurry, faded, or misaligned designs.

This article is your in depth guide to perfecting sublimation tumbler heat press settings. We will go over the basic supplies you will need, the many types of tumblers you can use, what works best as a substrate, setup techniques, what to do when things go wrong and best practices to make sure that you always get ideal results.

Key Takeaways

- High quality supplies and the right heat press machine is key to successful sublimation.

- Tumbler material will require different sublimation time and temperature.

- Thorough preparation of the tumbler and design will result in brilliant professional results.

- Many common sublimation issues like ghosting, fading, or uneven transfers can be resolved with easy at home fixes.

Essential Supplies for Sublimation Tumbler Heat Press

Before you begin the sublimation process for tumblers make sure you have all the right tools and materials. The quality of your supplies will reflect in your end result:

- Sublimation Blank Tumblers – we use coated tumblers which have a special sublimation finish that does a great job at accepting ink.

- Sublimation Printer & Ink — we either use a dedicated sublimation printer or have a standard inkjet that has been adapted to use sublimation inks.

- Sublimation Transfer Paper — we go for clear and crisp prints which is what this paper is for, also proper wrapping and taping is key.

- Heat Resistant Tape — this keeps your print in place during the press.

- Teflon Sheets or Heat Shrink Wraps – out for even pressure on stainless steel / insulated tumblers.

- Heat Resistant Gloves / Safety Equipment – a must have when you are working with hot tumblers.

Lint Free Cloth & Alcohol Wipes – for cleaning and to remove moisture before pressing.

Understanding Different Types of Tumblers

Not all tumblers are the same, and surface type plays a big role in material variations influEnciency of settings:

- Stainless Steel Tumbler Sublimation Very durable but do note that a careful balance of temp and time is required in the oven and with the press.

- Glass Tumblers These are heat sensitive which means lower temps and precise paper removal timing is a must.

- Ceramic Mugs Sublimation A classic choice which does a great job of retaining heat but does require longer press times.

- Plastic Tumblers May be used but only if they are coated for sublimation.

- Neoprene Sublimation – Soft drink sleeves and covers which do best with a pre press to remove wrinkles and moisture.

- Polyester Fabric Sublimation Great for wraps, sleeves and accessories because of their high heat tolerance.

- Knowing your substrates’ compatibility is key to always using the right metal sublimation settings, ceramic adjustments, or fabric specific prep.

Setting Up Your Tumbler Heat Press Machine

A proper heat press is key. Here’s what you do:

- Put the machine on a stable surface.

- Set the device to the right temp for tumbler sublimation.

- Use medium to high pressure setting based on the substrate.

- Set the press time by tumbler type.

- Do a run with scrap material before going live.

Also you may want to try out the convection oven method of sublimation against the heat press to see which works best for your workflow.

Preparing Your Tumbler for Sublimation

Preparation is the base for our best practices in sublimation which includes:

- Wash the tumbler and get out any moisture.

- Design print out and reduce it to size which is right.

- Wrap in transfer paper then secure with tape.

- Use shrink wrap or silicone bands for even pressure.

For fabrics (polyester, neoprene) pre press to remove wrinkles and moisture before sublimation.

Optimal Heat Press Settings for Tumblers

HeThere are different sublimation tumbler times and temperatures:

- 20 oz Stainless Steel Tumbler – 385°F (196°C), 60 sec, medium pressure

- Ceramic Mug Sublimation – 400°F (204°C), 3 min, firm pressure

- Glass Tumbler – 350°F (176°C), 2 min, light pressure

- Metal Sublimation Settings (Unisub products sublimation, coated metals) – Usually 400°F (204°C), 60 seconds, medium pressure

Always test first as time duration for oven and press may vary by machine and brand.

Tips for Flawless Sublimation Results

- Always replicate designs.

- Wrap transfer paper well.

- Tumble dry on low.

- Pay special attention to seams.

- Allow to cool before peeling off transfer paper after pressing.

Troubleshooting Common Sublimation Issues

- Faded prints out of the oven at a low temp setting or leave in too long.

- Ghosting issue with the tape job; use better transfer paper and proper taping.

- Even colors achieved with correct pressure which should be consistent.

- Burn marks a sign of over cooking – reduce time or temp in the tumbler.

Expanding Your Sublimation Projects

After tumblers, expand into:

- Ceramic mug sublimation

- Unisub products sublimation like plaques and coasters

- Polyester fabric sublimation for T-shirts and pillow covers

- Neoprene sublimation sleeves

- Metal sublimation settings for keychains and plates

This diversification strengthens your sublimation business.

Customizing Your Tumblers

Popular personalizations:

- Names and initials

- Brand identity

- Full wrap art

- Family photos

Unlimited creative input and choice of surface type make sublimation versatile and marketable.

Conclusion

The sublimation process for tumblers is easy once you know about substrate compatibility, proper sublimation heat press settings, and that which of temperature, press time, and pressure to use. By following best practices for even sublimation and paying close attention to transfer paper removal timing, you will get professional results each time.

As you work with stainless steel tumblers, ceramic mugs, polyester fabrics, neoprene, or metal sublimation projects, pay attention to the details which will give you long lasting and attractive prints.

With practice, use of heat resistant gloves for safe handling and compare the oven vs heat press methods out there — you can branch out into Unisub products sublimation and beyond turning blank items into pieces of art. read more