Beer Can Glass Sublimation is one of the fastest-growing trends in custom printing, allowing creators to transform plain drinkware into stylish, personalized pieces. Among all sublimation projects, beer can glasses stand out for their modern look, versatile use, and ability to showcase vibrant designs. However, achieving flawless results requires the right supplies, proper preparation, and a solid understanding of time and temperature settings.

In this guide, we’ll walk you through everything you need to know about beer can glass sublimation—covering essential materials, preparation tips, heat settings, techniques, creative design ideas, and long-term care. By the end, you’ll have a complete roadmap to creating professional-quality sublimated beer can glasses that both customers and gift recipients will love.

Key Takeaways

- Beer can glass sublimation is a cost-effective and creative way to customize drinkware.

- The right supplies, such as sublimation ink, paper, heat-resistant tape, and shrink wrap—are crucial for flawless results.

- Proper cleaning and preparation of the glass prevent print issues.

- Time and temperature control are the foundation of successful sublimation.

- Both convection ovens and mug presses work well, but each has unique benefits.

- Creative design approaches can elevate your sublimated glasses for personal use or commercial sales.

- With proper care, sublimated beer can glasses maintain their vibrant designs for years.

Essential Supplies for Beer Can Glass Sublimation

Before you begin, you’ll need to gather the right tools and materials. Missing even one item can affect your results. Here’s what you’ll need:

- Sublimation Printer and Ink – A specialized printer with sublimation ink ensures bright, long-lasting designs.

- Sublimation Paper – High-quality paper transfers designs cleanly without smudges.

- Beer Can Glass Blanks – Choose glasses specifically coated for sublimation. Regular glass won’t hold the print.

- Heat Source – Either a convection oven or a mug press (we’ll compare them later).

- Heat-Resistant Tape – Holds the design in place during the heating process.

- Shrink Wrap or Silicone Wrap – Ensures even pressure on the glass for better results.

- Heat-Resistant Gloves – Protects your hands when handling hot glasses.

- Lint Roller and Cleaning Cloth – Removes dust and oils from the glass surface before printing.

Investing in quality supplies pays off with more professional results and fewer wasted blanks.

Preparing Your Beer Can Glass for Sublimation

Preparation is the secret to achieving sharp, vibrant prints. Follow these steps:

- Clean the Surface – Wash the glass with soap and water to remove oils, then dry it completely. Use a lint roller or microfiber cloth to eliminate any dust particles.

- Print the Design – Mirror your artwork before printing it on sublimation paper. This ensures the image transfers correctly.

- Position the Design – Wrap the design around the glass, aligning carefully. Secure it with heat-resistant tape.

- Apply Shrink Wrap or Silicone Sleeve – This step ensures the paper makes full contact with the glass, preventing faded areas.

- Preheat Your Equipment – Whether you use an oven or mug press, make sure it reaches the correct temperature before starting.

Attention to detail during preparation can make the difference between a flawless glass and a wasted blank.

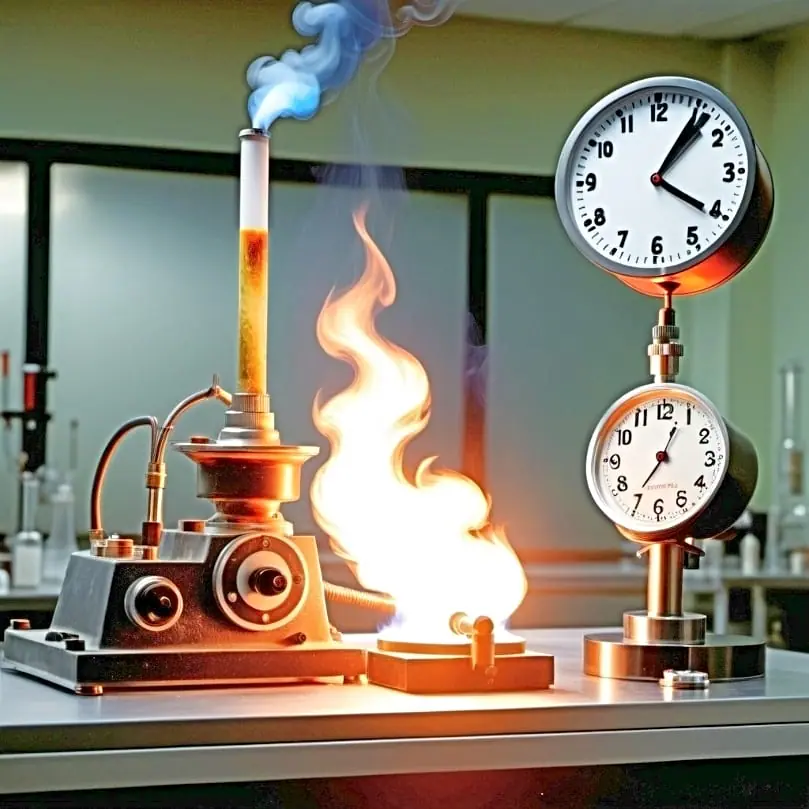

Mastering Time and Temperature for Beer Can Glass Sublimation

Getting the time and temperature right is critical. Too much heat can cause burns or ghosting, while too little will lead to dull prints.

- Standard Settings:

- Temperature: 375–400°F (190–205°C)

- Time: 4–6 minutes in a convection oven, or 2–3 minutes in a mug press

- Temperature: 375–400°F (190–205°C)

- Factors That Affect Settings:

- Thickness of the glass

- Type of wrap (shrink wrap or silicone)

- Quality of sublimation ink and paper

- Equipment calibration

- Thickness of the glass

Always run a few test prints when trying new blanks or designs. Keeping a log of your successful time and temperature combinations will save you future guesswork.

Sublimation Techniques: Convection Oven vs. Mug Press

Both convection ovens and mug presses are popular for sublimating beer can glasses, but they differ in performance:

Convection Oven

- Pros: Even heating, can process multiple glasses at once, great for bulk production.

- Cons: Requires shrink wrap, longer process time, larger workspace needed.

Mug Press

- Pros: Faster heating, no shrink wrap required, compact size.

- Cons: Can only press one glass at a time, uneven pressure if not positioned correctly.

Which should you choose?

- For small businesses or hobbyists, a mug press is convenient.

- For high-volume production, a convection oven offers efficiency and consistency.

Creative Ideas for Beer Can Glass Sublimation Designs

The beauty of sublimation lies in unlimited design potential. Some popular design ideas include:

- Business Branding – Logos, slogans, and promotional artwork for cafes, breweries, or shops.

- Seasonal Themes – Christmas, Halloween, summer vibes, or wedding-inspired designs.

- Personalized Gifts – Names, initials, or custom illustrations for birthdays and anniversaries.

- Trendy Aesthetics – Retro designs, gradients, abstract art, or minimalistic patterns.

- Photo Prints – Family pictures, travel shots, or pet portraits.

Experiment with color palettes and styles. High-resolution designs always yield the best results, so avoid low-quality images.

Caring for Your Sublimated Beer Can Glass

To keep your sublimated glass looking vibrant for years:

- Hand Wash Only – Avoid dishwashers, as high heat and harsh detergents can fade the print.

- Avoid Soaking – Prolonged soaking in hot water can weaken the coating.

- Use Gentle Cleaners – Stick to mild soap and soft sponges.

- Handle With Care – While sublimation is permanent, scratches on the glass can damage the design.

- Store Safely – Keep away from direct sunlight for extended periods to prevent fading.

Proper care ensures your hard work and creativity last long, especially for glasses sold to customers.

Conclusion

Beer can glass sublimation combines creativity, technology, and craftsmanship to produce stunning, personalized drinkware. From gathering the right supplies and carefully preparing your blanks, to mastering the balance of time and temperature, every step plays a crucial role in achieving professional results.

Whether you’re a small business owner looking to expand your product line or a hobbyist exploring sublimation, beer can glasses are an exciting canvas for endless design possibilities. With the right techniques and proper care, your sublimated glasses will not only impress but also stand the test of time.

If you’re ready to take your sublimation projects to the next level, start experimenting today—your perfect beer can glass design is just a print away!