Sublimation spray adhesive plays a vital role in sublimation printing by keeping transfer paper securely in place for clean and precise results. As sublimation transforms the world of custom apparel, promotional products, and personalized gifts, even the best designs and equipment can fall short if the transfer shifts during pressing.

Whether you’re working with soft polyester fabrics, shaped blanks, or complex prints, selecting the right spray adhesive and using it correctly can significantly improve your outcomes. In this guide, we’ll explain how sublimation spray adhesives work, how to apply them effectively, and how to avoid common mistakes that can frustrate both beginners and experienced users.

Key Takeaways

- Sublimation spray adhesive ensures accurate image transfers with minimal shifting.

- Proper application techniques are key to avoiding ghosting and residue.

- Choosing the right spray for fabric type and project complexity improves final results.

- Alternatives like heat transfer tape have pros and cons compared to spray adhesives.

- Maintenance of spray cans and workspace keeps performance consistent.

Exploring Sublimation Spray Adhesive

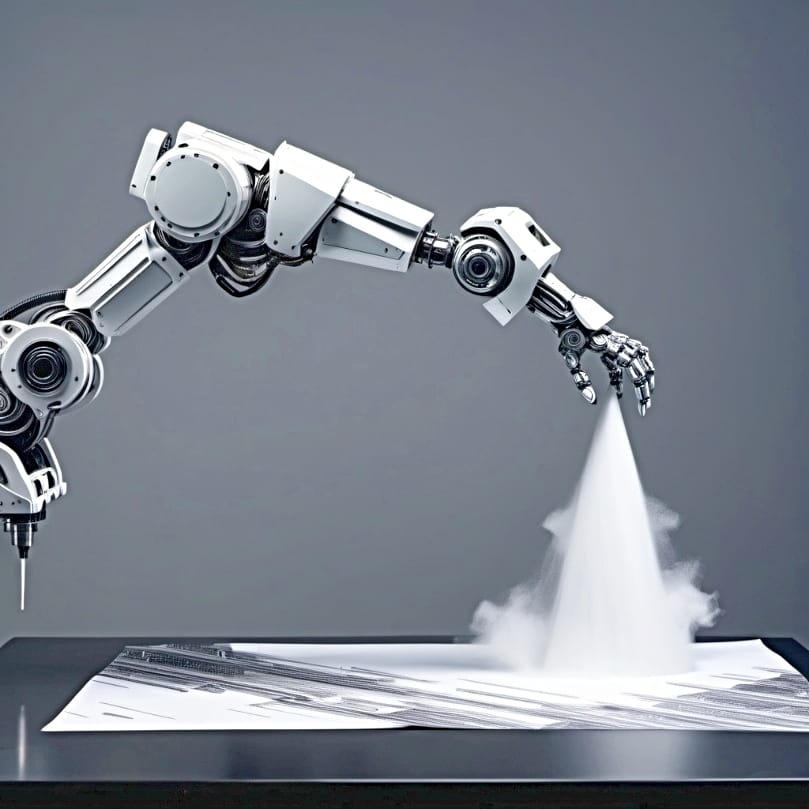

Sublimation spray adhesive is a temporary bonding agent used to hold sublimation paper in place on substrates like fabric during the heat press process. It prevents image shifting, ghosting, and misalignment by providing a light tack that disappears under heat.

The Application Process: How to Use Spray Adhesive with Sublimation Paper

Preparing Your Workspace

Ensure your work surface is clean and free of lint or debris. Use parchment paper or a protective sheet to avoid overspray on your table. Ventilation is also important, as most sublimation sprays contain chemicals.

Spraying Techniques

Shake the adhesive well before use. Hold it 6–8 inches from the sublimation paper and spray a light, even coat on the back side of the print. Avoid over-spraying, as it can leave residue or make the paper too tacky.

Aligning and Pressing

After spraying, carefully place the paper onto the fabric or substrate. Press lightly to bond, then proceed to the heat press. The adhesive will hold the paper in place while the heat sublimates the ink into the material.

Choosing the Right Adhesive for Soft Sublimation Materials

For soft textiles like polyester T-shirts or pillowcases, choose a sublimation spray that offers:

- Low residue

- Quick tack

- Heat-activated dissipation

Avoid sprays intended for hard surfaces or crafting, as they may leave marks or affect ink penetration.

Avoiding Common Issues with Adhesive Spray

Common mistakes include:

- Over-application: Causes blotchy transfers or sticky residue.

- Poor alignment: Leads to ghosted or doubled images.

- Low-quality spray: May not hold during pressing, especially at high temperatures.

Pro tip: Test on a scrap fabric before a full run.

Comparing Adhesive Sprays vs. Heat Transfer Tape

| Feature | Spray Adhesive | Heat Transfer Tape |

| Ease of Use | Fast & covers the full area | Precise but time-consuming |

| Residue Risk | Possible if overused | Minimal |

| Best For | Soft/flexible materials | Rigid items like mugs |

| Reusability | No | Yes (sometimes) |

Adhesive sprays work better on soft and uneven surfaces, while tape is great for firm positioning on rigid blanks.

Specialty Projects: Using Spray Adhesive for Complex Sublimation Prints

When working with curved or irregular items (e.g., caps, neoprene sleeves), sublimation spray adhesive helps hold transfers in place where tape can’t. For example:

- Use a jig or wrap along with spray for better hold on mugs.

- On shaped garments (e.g., socks, sleeves), it ensures edge-to-edge coverage without shifting.

Maintaining Your Spray Adhesive for Optimal Performance

- Storage: Keep upright in a cool, dry place.

- Nozzle care: After each use, spray for 1 second upside-down to clear nozzle.

- Shelf life: Check expiry date – old sprays can clog or lose effectiveness.

- Clean-up: Use rubbing alcohol to remove excess spray from surfaces.

Conclusion

Sublimation spray adhesive is a valuable tool for achieving crisp, high-quality transfers, especially on soft or irregular materials where traditional methods fall short. By understanding how to apply it correctly, selecting the right formula for your substrate, and avoiding common mistakes like over-spraying or misalignment, you can dramatically improve the consistency and quality of your sublimation results.

Whether you’re creating apparel, specialty items, or complex prints, the right spray adhesive can make your workflow faster, cleaner, and more professional. With proper handling and maintenance, it becomes an essential part of any serious sublimation setup.