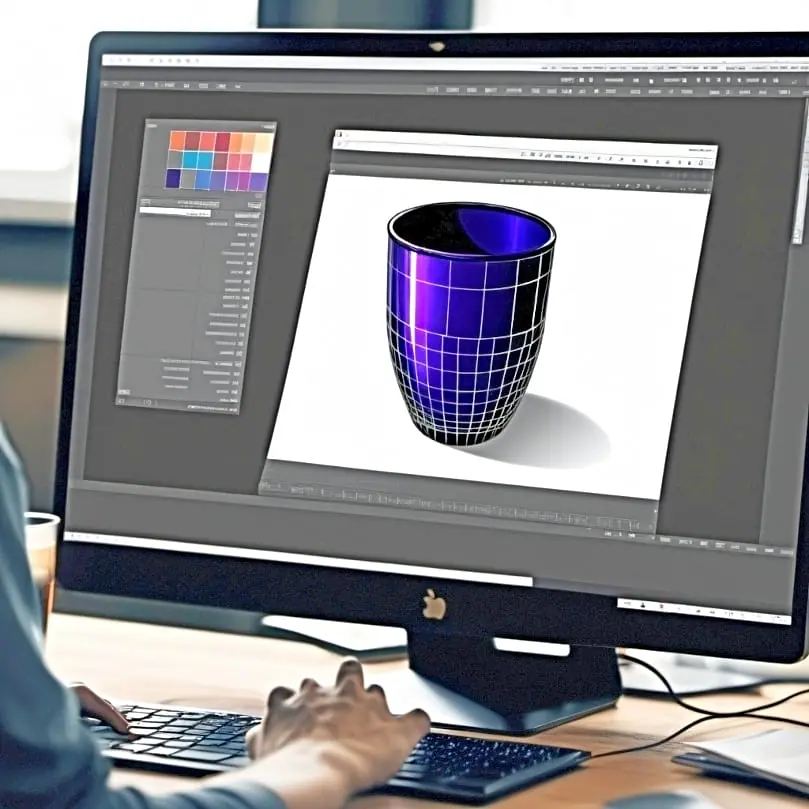

Sublimation printing has quickly become one of the most popular methods for creating personalized products and custom gifts. From birthdays and weddings to corporate branding and promotional events, sublimated tumblers stand out as both stylish and durable. What makes them even more attractive is their ability to showcase high quality, full color designs that don’t peel, fade, or wash off.

However, achieving professional-level results with sublimation doesn’t happen by chance. The most important factor in this process is setting up and using your sublimation heat press settings correctly. If your press time, temperature settings, or pressure settings are off, you may end up with blurry, faded, or misaligned designs.

This article is your complete guide to mastering sublimation tumbler heat press settings. We’ll walk through essential supplies, tumbler types, substrate compatibility, setup techniques, troubleshooting tips, and best practices to ensure that you consistently achieve flawless results.

Key Takeaways

- High-quality supplies and the right heat press machine are crucial for sublimation success.

- Different tumbler materials require different sublimation tumbler times and temperatures.

- Proper preparation of both the tumbler and design leads to vibrant, professional prints.

- Common sublimation issues such as ghosting, fading, or uneven transfers can be fixed with simple adjustments.

Essential Supplies for Sublimation Tumbler Heat Press

Before diving into the tumbler sublimation process steps, make sure you have the right tools and materials. The quality of your supplies directly impacts your final results:

- Sublimation Blank Tumblers These coated tumblers for sublimation come with a special sublimation coating or finish that absorbs ink effectively.

- Sublimation Printer & Ink Either a dedicated sublimation printer or a converted inkjet printer with sublimation ink cartridges.

- Sublimation Transfer Paper For clear and crisp prints; proper transfer paper wrapping and taping is essential.

- Heat-Resistant Tape Keeps your printed design aligned during pressing.

- Teflon Sheets or Heat Shrink Wraps Ensures even pressure for stainless steel / insulated tumblers.

- Heat-Resistant Gloves / Safety Equipment A must when handling hot tumblers.

- Lint-Free Cloth & Alcohol Wipes For cleaning and moisture elimination before pressing.

Understanding Different Types of Tumblers

Not all tumblers are the same, and surface type plays a big role in material variations influencing settings:

- Stainless Steel Tumbler Sublimation Popular for durability; requires careful balance of temperature settings and time duration for oven and press.

- Glass Tumblers Heat-sensitive; need lower temperatures and precise transfer paper removal timing.

- Ceramic Mug Sublimation A classic; retains heat well but requires longer press times.

- Plastic Tumblers Only usable if coated for sublimation.

- Neoprene Sublimation Soft drink sleeves and covers that need pre-pressing fabric to eliminate wrinkles and moisture elimination.

- Polyester Fabric Sublimation Ideal for wraps, sleeves, and accessories due to high heat tolerance.

Understanding substrate compatibility ensures you always use the right metal sublimation settings, ceramic adjustments, or fabric-specific preparation steps.

Setting Up Your Tumbler Heat Press Machine

A well-prepared heat press is essential. Here’s how:

- Place the machine on a stable surface.

- Preheat to the desired temperature for tumbler sublimation.

- Adjust medium vs high pressure sublimation depending on the substrate.

- Set press time according to tumbler type.

- Test with scrap material before starting production.

You can also compare the convection oven sublimation method vs heat press method for tumblers to see which works best for your workflow.

Preparing Your Tumbler for Sublimation

Preparation is key for best practices for uniform sublimation:

- Clean the tumbler and ensure moisture elimination.

- Print and cut your design to fit.

- Wrap with transfer paper, tape tightly.

- Use shrink wrap or silicone wraps for uniform pressure.

- For fabrics (polyester, neoprene), pre-press fabric to remove wrinkles and moisture before sublimation.

Optimal Heat Press Settings for Tumblers

Here are general sublimation tumbler times and temperatures:

- 20 oz Stainless Steel Tumbler 385°F (196°C), 60 seconds, medium pressure

- Ceramic Mug Sublimation 400°F (204°C), 180 seconds, firm pressure

- Glass Tumbler 350°F (176°C), 120 seconds, light pressure

- Metal Sublimation Settings (Unisub products sublimation, coated metals) Typically 400°F (204°C), 60 seconds, medium pressure

Always test first, as time duration for oven and press may vary by machine and brand.

Tips for Flawless Sublimation Results

- Always mirror designs.

- Wrap transfer paper securely.

- Rotate tumblers for even heating.

- Pay extra attention to seam areas.

- Let cool before removing transfer paper after pressing.

Troubleshooting Common Sublimation Issues

- Faded Prints Low temperature settings or press time.

- Ghosting Poor taping; improve transfer paper wrapping and taping.

- Uneven Colors Wrong pressure settings (too low or uneven).

- Burn Marks Excessive time duration or temperature for tumbler sublimation.

Expanding Your Sublimation Projects

After tumblers, expand into:

- Ceramic mug sublimation

- Unisub products sublimation like plaques and coasters

- Polyester fabric sublimation for T-shirts and pillow covers

- Neoprene sublimation sleeves

- Metal sublimation settings for keychains and plates

This diversification strengthens your sublimation business.

Customizing Your Tumblers

Popular personalization ideas:

- Names and initials

- Corporate branding

- Full-wrap art

- Family photos

Creative freedom and surface type variety make sublimation versatile and marketable.

Conclusion

The tumbler sublimation process steps are straightforward when you understand substrate compatibility, correct sublimation heat press settings, and the right balance of temperature, press time, and pressure settings. By following best practices for uniform sublimation and carefully managing transfer paper removal timing, you’ll achieve professional results every time.

Whether working with stainless steel tumblers, ceramic mug sublimation, polyester fabric sublimation, neoprene sublimation, or metal sublimation settings, attention to detail ensures long-lasting, eye-catching prints.

With practice, safe handling using heat-resistant gloves, and comparing the oven vs heat press methods, you can expand into Unisub products sublimation and beyond—turning simple blanks into works of art.