Sublimation paper is essential for creating vibrant, durable images through sublimation printing on a wide range of surfaces, from fabrics to ceramics. If you’re a creative professional or hobbyist aiming to take your printing projects to the next level, understanding sublimation paper is crucial. This complete guide will break down what sublimation paper is, how it works in the printing process, and why it’s a must-have tool for designers, artists, and small businesses. By the end, you’ll be confident in choosing the right sublimation paper to enhance the quality and impact of your creative work.

Key Takeaways

- Not all sublimation papers are the same. Coating quality, paper weight (gsm), and drying time affect image clarity and ink transfer.

- High-quality sublimation paper offers better ink absorption, reduces smudging, and enhances color vibrancy for textiles, ceramics, and coated surfaces.

- Paper compatibility with printers and inks is crucial – Always use paper that matches your specific sublimation printer and ink type for best results.

- Test different brands – Some papers may deliver richer colors or better durability depending on your project requirements.

The right paper + the right equipment = professional-quality results. Sharp detail, vibrant colors, and long-lasting prints come from using the correct materials.

Understanding Sublimation Paper: A Comprehensive Overview

Sublimation paper plays a crucial role in dye-sublimation printing by acting as the medium between your digital design and the final product. It is specially coated to absorb sublimation inks and release them efficiently when exposed to heat and pressure. This process turns the ink into gas, allowing it to bond permanently with the surface of fabrics, ceramics, or metals, resulting in vibrant, long-lasting prints.

The quality of sublimation paper directly affects color accuracy, detail, and overall print results. High-grade papers offer better ink release, faster drying times, and reduced waste, making the process more efficient and cost-effective. Available in various weights and sizes, sublimation paper can be selected based on project type, from apparel to rigid substrates. As printing technology evolves, choosing the right sublimation paper remains essential for achieving professional, eye-catching results.

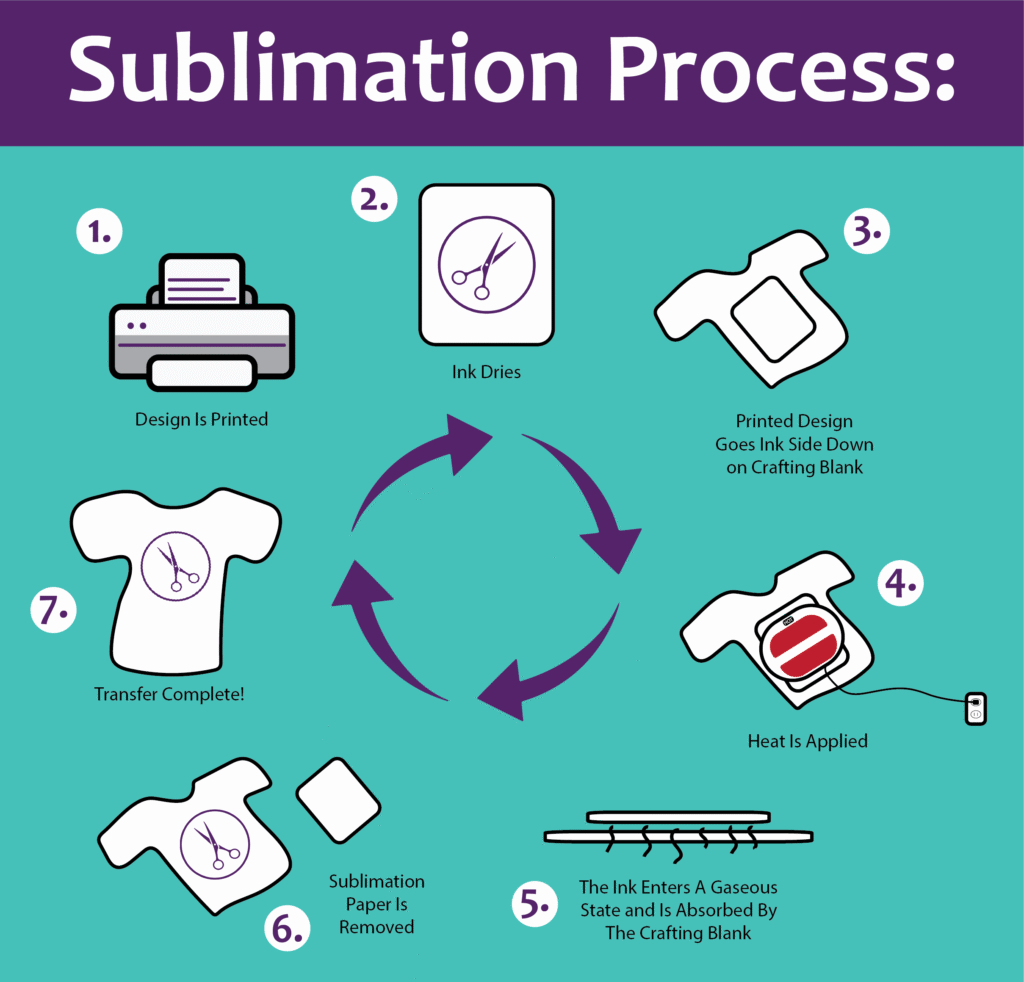

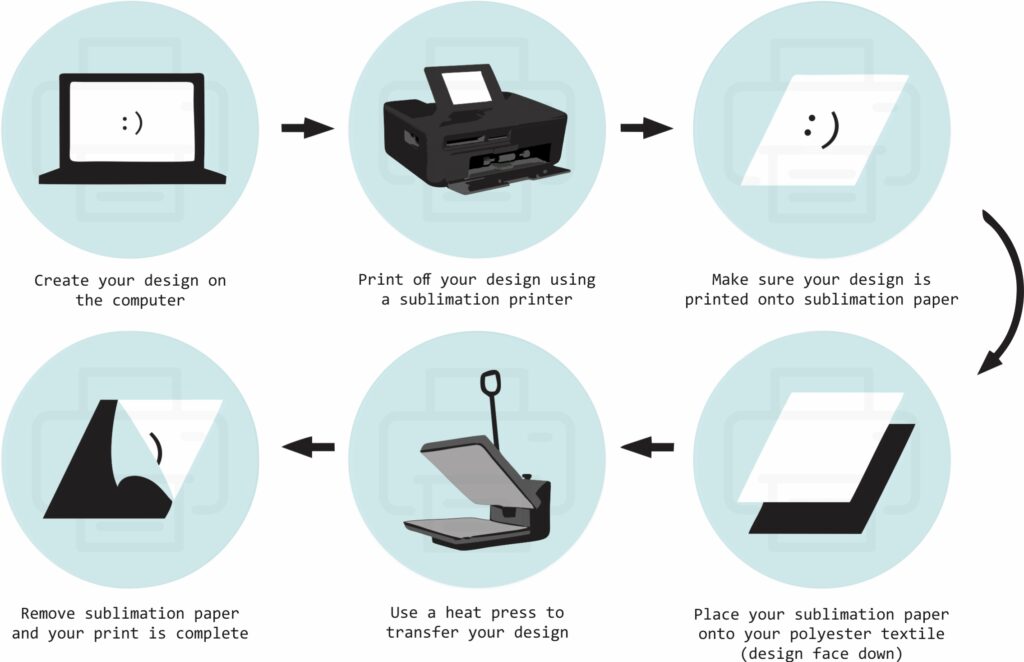

How Sublimation Paper Works in the Printing Process

Sublimation paper is used for the temporary application of sublimation ink which is printed via a compatible inkjet printer. In the heat press process the ink changes from a solid to a gas state without going through a liquid phase – a process which is called sublimation. The gas then goes into the polyester layer of the substrate which in turn produces a permanent and very vivid image that does not crack, peel or fade.

Key elements which play a role in this process are:

- Temperature which is usually between 350°F to 400°F

- Time which is usually 30 – 60 seconds based on the type of material

- Pressure which is of medium to firm degree based on the substrate material

Also each of these elements must be just right along with the quality of the sublimation paper for best results.

Types of Sublimation Paper

There are different types of sublimation papers available depending on your printing needs. Here are the most common ones:

1. Lightweight Sublimation Paper (100–120 gsm)

- Ideal for high-speed printers

- Dries quickly and works well for textiles

- Less suited for hard substrates

2. Medium-weight Sublimation Paper (120–130 gsm)

- A balanced option for both fabrics and rigid items

- Reduces curling and smudging

3. Heavyweight Sublimation Paper (above 130 gsm)

- Best for ceramic mugs, metal sheets, wood, and coated rigid surfaces

- Offers high ink absorption and reduced warping

Choosing the Best Sublimation Paper: What to Look For

When selecting sublimation paper, consider the following criteria to ensure optimal results:

✔ Ink Compatibility

Make sure the paper is designed for use with sublimation inks, especially if you’re using branded inks (e.g., Sawgrass, Epson, etc.).

✔ Printer Compatibility

Some sublimation papers perform better with certain printers. Check if the paper supports your printer model (desktop vs. industrial).

✔ Drying Time

Fast-drying papers reduce the chances of smudging and ghosting, especially when mass producing items.

✔ Coating Quality

Look for papers with even, smooth coating. A high-quality coating ensures better ink release and sharper image transfer.

Common Applications of Sublimation Paper

Sublimation paper is incredibly versatile and is used across many creative and commercial industries. Here are some popular applications:

- Custom T-shirts and apparel (must be polyester or polyester-coated)

- Mugs, tumblers, and drinkware

- Mousepads, keychains, and phone cases

- Home décor items like photo slates and pillows

- Promotional products and corporate gifts

Tips for Perfect Sublimation Transfers

To ensure professional-looking results every time, follow these best practices:

- Pre-press your fabric or item to remove moisture and wrinkles

- Use heat-resistant tape to secure the sublimation paper

- Do not reuse sublimation paper after a transfer — it’s single-use only

- Store paper properly in a cool, dry place to maintain print quality

Conclusion

Whether you’re a small business owner, a creative hobbyist, or a professional designer, using the right sublimation paper can make or break your final product. It’s not just about the design or equipment — it’s about how everything works together.

Investing in high-quality sublimation paper ensures color accuracy, detailed prints, and satisfied customers. As you experiment with different brands and weights, you’ll discover which combination delivers the results you want.